I-GMSB-03 Auto Part Water Pump OE 9025153 Ifanelekile kwiCruze 2009-2016

1.Le yimpompo yamanzi eqhelekileyo yoomatshini;uninzi lweenjini okwangoku zisebenzisa iimpompo zamanzi ezinomatshini.Impompo yamanzi esebenza ngoomatshini iqhutywa yi-crankshaft ye-injini ngaphandle (njengebhanti lokuhambisa), kwaye isantya sayo silingana nesantya se-injini.Xa i-injini isebenza phantsi kwesantya esiphezulu kunye neemeko zomthwalo onzima, i-injini ivelisa ubushushu obuninzi, kwaye isantya esiphezulu sempompo yamanzi sandisa ukuhamba kokujikeleza kwesipholisi, esiphucula nje amandla okupholisa enjini.Iyakwazi ukudlulisela amandla oomatshini (ujikelezo) kuwo ukusuka enjinini.Amandla enziweyo) aguqulwa abe ngamandla anokubakho (oko kukuthi ukuphakamisa) kunye namandla ekinetic (oko kukuthi isantya sokuhamba) kolwelo (amanzi okanye isinqandi-kukhenkceza).Iimpompo zamanzi eziziimoto ziimpompo ze-centrifugal.Umsebenzi wayo kukumpompa into epholisayo ukuze isipholileyo sihambe kumjelo wokupholisa we-injini ukususa ubushushu obuveliswayo xa injini isebenza kwaye igcine ubushushu obuqhelekileyo bokusebenza be-injini.Ezona ntsilelo zixhaphakileyo kwiinjini zemoto, ezinje ngepiston scuffing, detonation, ukuvuza kwangaphakathi kwe-cylinder punch, ingxolo enkulu eveliswayo, ukuhla kwamandla okukhawulezisa, njl. injini yemoto Kwaye kubangele.

2. Ngokwezibalo, kwihlabathi, i-20% yokungaphumeleli kwe-injini yomthwalo wokukhanya ivela ekungaphumeleli kwenkqubo yokupholisa, kwaye i-40% yokungaphumeleli kwe-injini yomthwalo onzima ivela ekungaphumeleli kwenkqubo yokupholisa.Ke ngoko, isayensi kunye nokugcinwa okufanelekileyo kweenkqubo zokupholisa kubaluleke kakhulu ekusebenzeni okuqhelekileyo kweenjini zemoto.

3.Kukho iindawo ezintlanu eziphambili zempompo yamanzi: izindlu, ukuthwala, ukutywinwa kwamanzi, i-hub / pulley kunye ne-impeller.Kukwakho nezinye izincedisi, ezinje ngee-gaskets, ii-O-rings, iibholiti, njl.

4. Isingxobo sempompo yamanzi: Isingxobo sempompo yamanzi sisiseko apho zonke ezinye iindawo zifakelwe kwaye ziqhagamshelwe kwi-injini.Ngokuqhelekileyo yenziwe ngentsimbi etyhidiweyo okanye i-aluminium etyhidiweyo (iinkqubo zokuphosa kunye ne-die-casting).Ikwayenziwe nge-PM-7900 (i-resin yothuli. Kwaye imathiriyeli yentsimbi epholileyo. Le modeli yigobolondo ye-aluminiyam ye-gravity-cast.

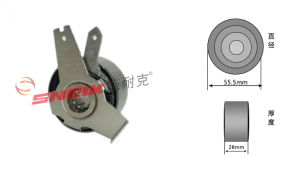

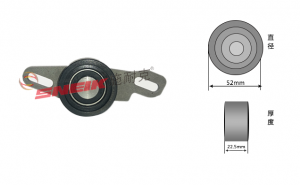

I-5.Ukuthwala: Kuyimfanelo enkulu yokuhanjiswa kwamandla.Iqulunqwe ngamalungu amaninzi aphambili afana ne-mandrel, ibhola yensimbi / i-roller, i-ferrule, i-cage, i-seal, njl.Ukuthwala kuluhlu lwebhola ephindwe kabini (uhlobo lweWB).

I-Wheel hub: Iimpompo zamanzi ezininzi azinazo iipuli, kodwa zineziko.Olu hlobo luyi-disc hub, kwaye izinto zalo ziyi-ductile iron pulley / hub.

I-Impeller: I-impeller yenziwe ngencakuba yeradial okanye emile okwe-arc kunye nomzimba, kwaye isebenzisa itorque ejikelezayo eyaziswa yi-bearing shaft ukumpompa into epholileyo kwisixokelelwano sokupholisa se-injini ukuze sijikeleze.Isixhobo esigqibezela uguqulo lwamandla, ngokujikeleziswa, sikhawulezisa ukuhamba kolwelo, sigqibezela umjikelo wokupholisa kunye nokufudumeza kwamanzi okanye isithinteli sokukhenkceza, kwaye sifezekise injongo yokupholisa injini.Le yintsimbi epholileyo eqengqelekayo.

Isitywina samanzi sisixhobo sokutywina sempompo yamanzi.Umsebenzi waso kukutywina isisipholisi ukunqanda ukuvuza, kwaye kwangaxeshanye ukwahlula isisipholisi kumbhobho wamanzi ukukhusela ukuthwala.Amacandelo ayo aphambili asebenzayo yiringi ehambayo kunye ne-static ring.I-static ring igxininiswe kwigobolondo, kwaye ikhonkco ehambayo ijikeleza kunye ne-shaft.Ngexesha lenkqubo, iiringi eziguquguqukayo kunye ne-static zikhuhla omnye komnye kwaye kufuneka zigcinwe zivaliwe.Izinto eziphathekayo zendandatho eziguquguqukayo ngokuqhelekileyo zenziwe nge-ceramics (uqwalaselo oluqhelekileyo) kunye ne-silicon carbide (ubumbeko oluphezulu), kwaye iringi ye-static yenziwe ngokubanzi ngegraphite (ubumbeko oluqhelekileyo) okanye i-carbon graphite (ubumbeko oluphezulu).) Ngoku iimveliso zethu zonke zenziwe nge-carbon graphite izinto ezikumgangatho ophezulu.

(1) Fakela iringi yerabha etywiniweyo endaweni phambi kokufaka impompo yamanzi

(2) Emva kokuba kufakwe impompo yamanzi, kuyimfuneko ukufumanisa izithuba ezinqamlekileyo kunye nezithe nkqo phakathi kokungena kwamanzi kwimpompo yamanzi kunye nokudibanisa kwentloko ye-cylinder.Igeyiji yokulinganisa ingcali isetyenziselwa ukubona umsantsa wexesha elide phakathi kokungena kwamanzi kwimpompo kunye nentloko yesilinda ukuqinisekisa ukuba iyahlangabezana neemfuno)

(3) Umphezulu wofakelo lwempompo kufuneka ucocwe ngononophelo kwaye ulinganiswe

(4) Xa ufaka impompo yamanzi, iringi yerabha etywiniweyo yempompo yamanzi kufuneka imanziswe ngesisipholisi kuqala.Ukuba i-sealant iyafuneka, kufuneka kuthathelwe ingqalelo ukuba ungafaki kakhulu

(5) Xa utshintsha impompo yamanzi, inkqubo yokupholisa kufuneka icocwe, kuba ubumdaka, umhlwa kunye nezinye izinto zangaphandle kwinkqubo yokupholisa ziya kubangela imikrwelo kumphezulu wokutywinwa kwesitywina samanzi, okukhokelela ekuvuzeni kwempompo yamanzi.

(6) Sebenzisa ukupholisa okukumgangatho ophezulu, ungazalisi ukupholisa okusele kusetyenziswe kunye nomgangatho ophantsi, kuba ukupholisa okukumgangatho ophantsi okanye amanzi akanazo izinto ezikhusela umhlwa, nto leyo eya kubangela ngokulula ukubola kwenkqubo yokujikeleza kunye nomzimba wempompo yamanzi. ukukhawulezisa ukuwohloka kwetywina lamanzi Ukonakala kunye nokuguga ekugqibeleni kuya kukhokelela ekuvuzeni kwempompo yamanzi (yongeza uphawu oluqhelekileyo lwesithinteli sokukhenkceza esihlangabezana nemigangatho yesizwe).Kuyacetyiswa ukuba kusetyenziswe i-antifreeze ekhethekileyo yenkampani

(7) Amandla oxinzelelo lwebhanti yempompo yamanzi kufuneka afaneleke, kwaye kufuneka asetyenziswe ngokungqongqo ngokuhambelana nemigaqo yohlengahlengiso.Ukuba i-tension force incinci kakhulu, ibhanti iya kukhupha kwaye ibangele ingxolo, kwaye kwiimeko ezinzulu, impompo yamanzi ayiyi kusebenza ngokuqhelekileyo.Ukunyanzeliswa okugqithisileyo kwebhanti kuya kubangela ukuba ukuthwala kugqithise kwaye kubangele umonakalo kwangethuba, kwaye ukuthwala kuya kuphuka.